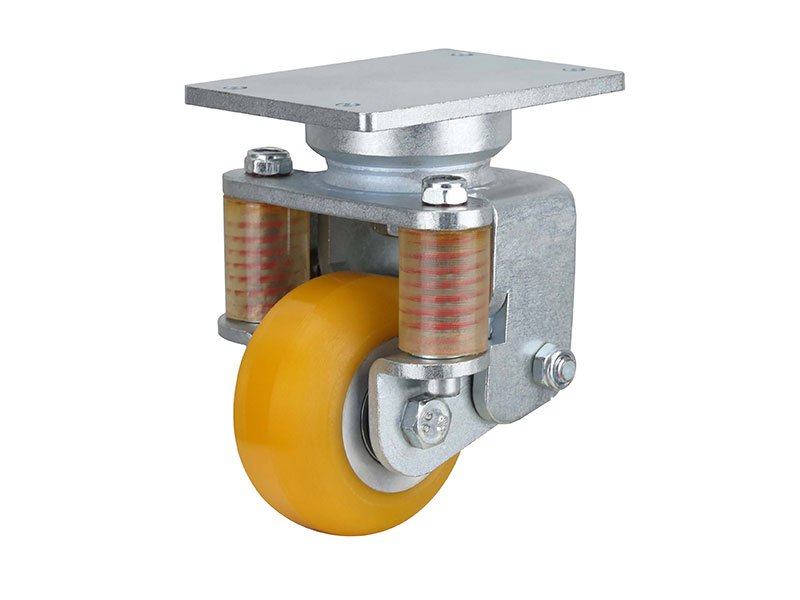

Balancing Caster wheels for Forklift AGV (350kg)

Material upgrading:6061 aluminum wheel core thanks to light weight.

Accurate CPU casting makes wheel more wear-resistant and anti-aging.

Shock absorption parts Strengthening: Both spring and high elastic PU can absorb the vibration formed during the moving process of AGV, and the appropriate shock absorption stroke helps the AGV to maintain the stable posture when steering.

Overall structure optimization: the overall front shock absorption structure realizes the minimum rotating radius of the caster, which meets the design requirements of the compact activity space of the balance caster wheels. The steering structure of the combination of plane bearing and cone bearing has small steering force and is more impact-resistant.

Environmental-friendly: Comply with international ROHS standards

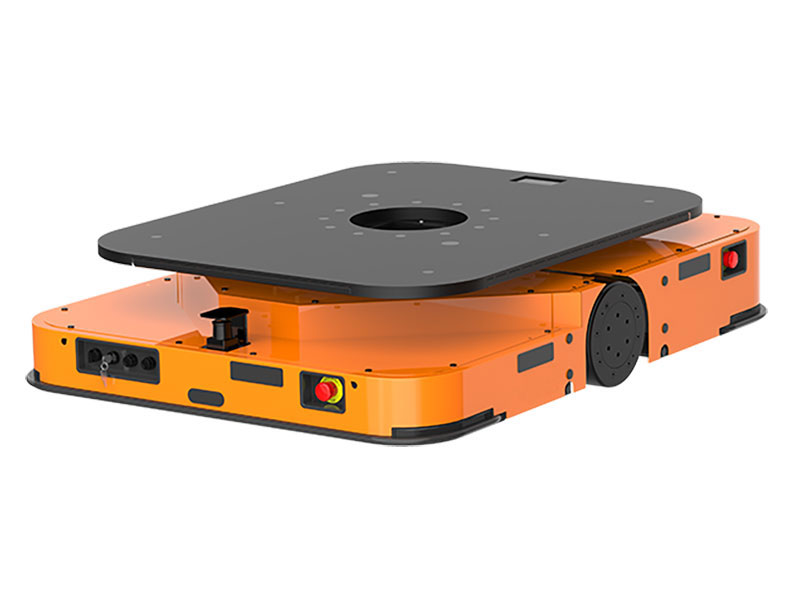

Latent AGV driven wheel (500kg)

Material upgrading: steel wheel core, accurate CPU casting makes the wheel wear-resistant, anti-aging.

Installation height: while considering the movement speed, load performance and service life, achieve the lowest installation height, which make the latent AGV have a lower posture possibility. Structural optimization: the steering structure of plane bearing and conical bearing is more flexible and more impact-resistant. The steering compensation effect of the two-wheel structure makes the steering force required by the driven wheel smaller and saves the energy consumption of the equipment.

Environmental-friendly: comply with international ROHS standards

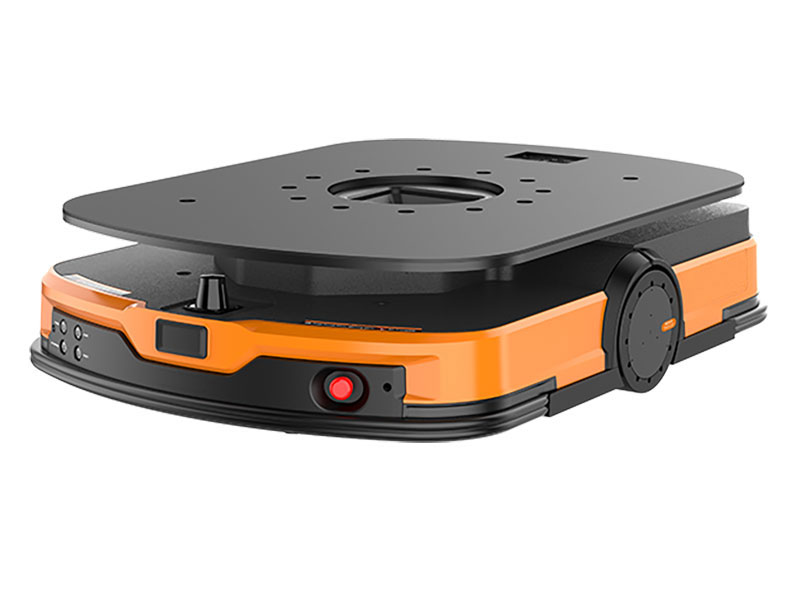

Latent AGV driven wheel (400kg)

Material upgrading: steel wheel core, accurate CPU casting makes the wheel wear-resistant, anti-aging.

Installation height: Base integrated forging molding. In addition,CNC precision machining, taking into account the moving speed, load performance and service life at the same time, this AGV caster wheels can achieve the lowest installation height.

Structural optimization: the steering structure of plane bearing and conical bearing is more flexible and more impact-resistant. The steering compensation effect of the two-wheel structure makes the steering force required by the driven wheel smaller and saves the energy consumption of the equipment.

Environmental-friendly: comply with international ROHS standards

Transplantable AGV driven wheel (600-1000kg)

Steel wheel core, high quality CPU casting wheel surface, double wheel structure, wear-resistant, anti-aging, no trace.

This kind of steering structure with different eccentricities through the crankshaft or two eccentric bearings can adjust the rotation radius in different directions according to the AGV/AMR.

Thus, it can prevent AGV/AMR from deviating from the specified route because the rotation radius of the driving wheel is too large, and also avoid the drive unit transition load caused by the eccentricity of the driving wheel is too small and the steering resistance is too large.

Super-heavy duty AGV driven wheel (1000-3000kg)

Iron wheel core, high quality CPU casting wheel surface, wear-resistant, anti-aging, no trace.

The shock absorption structure of spring or spring-reinforced polyurethane blocks can absorb the vibration caused by bumps when the AGV moves on uneven ground and reduce noise, thereby protecting the vibration sensitive cargo from damage.

The 18mm shock absorption formation, even in the uneven ground, can also maximize the guarantee that the caster at all times contact the ground, will not cause the separation of the caster and the ground to cause the AGV body to lose balance or deviate from the specified route.

In addition, depending on the requirements of different initial and maximum damping loads, the brand will provide damping components with different elastic characteristics.

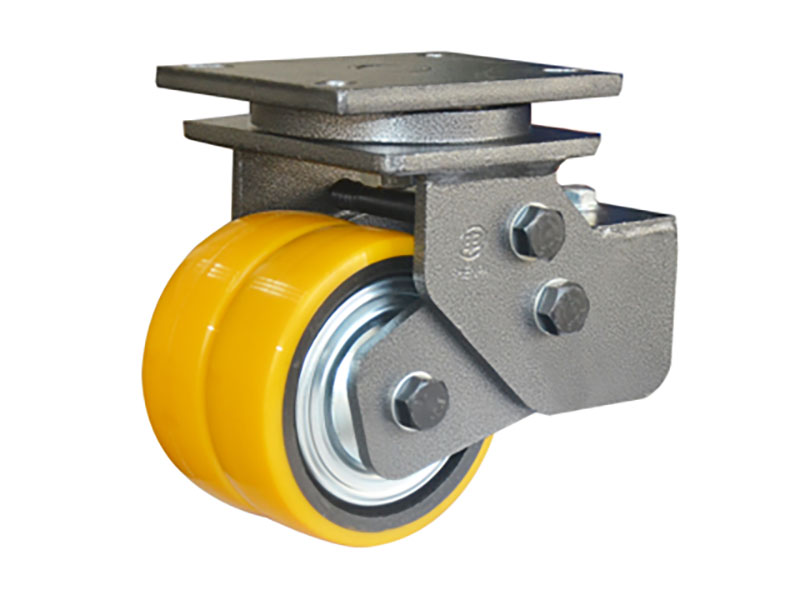

Heavy duty AGV driven wheel (600-1700kg)

Iron wheel core, high quality CPU casting wheel surface, wear-resistant, anti-aging, no trace.

Base forming, CNC precision machining, with flat bearings and cone bearings, to achieve quiet and ultra-long service life.

The shock absorption component of the double spring can absorb the vibration caused by bumps when the AGV moves on the uneven ground, and reduce noise, thereby protecting the vibration sensitive cargo from damage.

The formation of 15mm shock absorption, even in the uneven ground, can maximize the guarantee that the caster is always in contact with the ground, and will not cause the AGV body to lose balance or deviate from the specified route because of the separation of the caster and the ground.

In addition, depending on the requirements of different initial and maximum damping loads, the brand will provide damping components with different elastic characteristics.

McNamm Wheel (1000-3000kg)

7075 alloy aluminum wheel core and hub, 40Cr roller, high strength, light weight.

CNC precision machining, high concentricity, simple disassembly, convenient later maintenance.

The surface of the wheel is hard anodized and corrosion-resistant.

High-end CPU casting wheel surface, wear resistance, tear resistance. shoreA 95° wheel hardness, to ensure the coefficient of friction at the same time can better protect the ground.

In addition, for different wheel diameter or load, and different installation methods such as flanges or keyways, we can provide different design solutions according to your requirements.